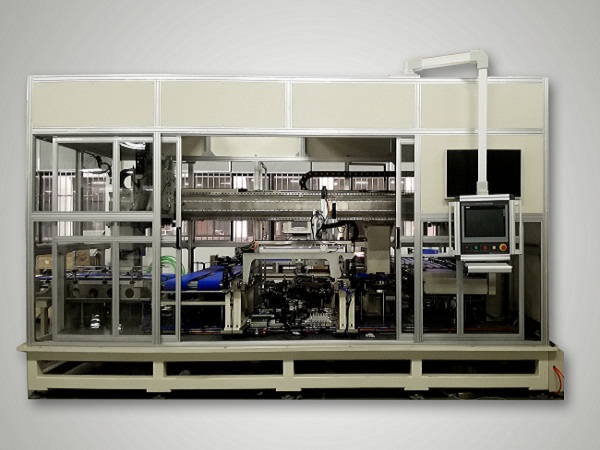

Bearing online inspection

This series of products can be connected with the grinder to implement online automatic detection, online sorting to improve processing quality, SPC analysis to achieve pre-control production, closed-loop feedback to replace manual labor, and to achieve one person with multiple machines or unattended.

Bearing online testing equipment related data

Measuring range: bearing inner diameter, outer diameter, inner raceway, outer raceway

Measurement parameters

1. The average size deviation of the inner diameter of the inner ring, taper, ovality (optional), busbar profile (optional);

2. Average size deviation of outer ring outer diameter, taper, ovality (optional), busbar profile (optional)

3. Single size deviation and angle of inner raceway;

4. Single dimension deviation and angle of outer raceway;

Measurement method: gas measurement/electric measurement optional, or electric measurement.

Measurement accuracy: ±1μm

Measuring cycle: meet the grinding cycle

Temperature compensation: fast temperature measurement and temperature compensation

Code reading function: realize the reading of two-dimensional code of parts

SPC function: automatic data acquisition, calculation and analysis, providing XbaR control chart and process control parameters such as CP/CPK/PP/PPK/CMK

Feedback function: This machine can form a closed-loop control unit with the grinding machine to realize unattended grinding.

Features of Bearing Online Testing Equipment

1. High quality assurance: Bearing online testing machine has online automatic sorting function, qualified products flow into the next process, and NG products are rejected;

2. Save labor: Bearing online testing equipment can form a closed-loop system with the machine tool, and realize feedback to guide the automatic parts adjustment of the machine tool. It is an inevitable choice to realize "one person with multiple machines" or even "unmanned factory";

3. Pre-control target: This series of inspection machines have the ability of SPC process control analysis. Through the full inspection data, the long-term and short-term capability index of the corresponding machine tool can be obtained. When the equipment is in "unsteady" operation, it can timely remind operators and managers to carry out the equipment. Adjust to achieve the quality management goal of "pre-control".

豫公网安备 41030502000429号

豫公网安备 41030502000429号