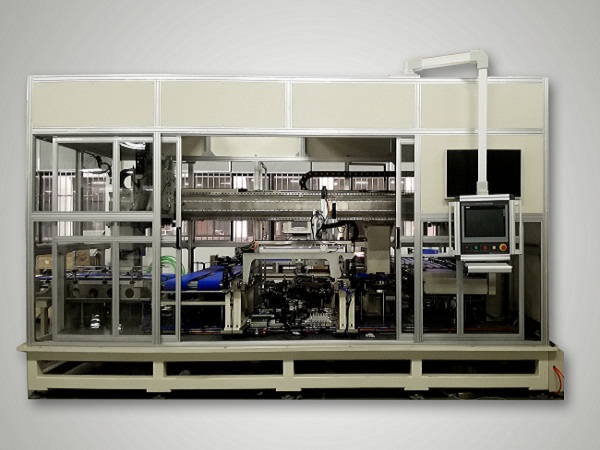

Eddy current testing equipment

The eddy current flaw detection equipment produced by CAYA is mainly an automatic eddy current flaw detection equipment for ferrule detection. The outer diameter of the bearing ranges from 220-600mm. Depending on the HMI manual input or electronic input, the device will automatically complete the (different) bearing type change. The equipment can automatically change between inner and outer rings of the same bearing type without external input.

Working principle of eddy current testing equipment: Using the eddy current testing principle to test the workmanship of the bearing material, it can be found whether there are cracks, depressions and other defects on the bearing surface.

Eddy current flaw detection equipment components: including oscillator, probe coil, signal detection device, measurement comparison circuit, signal processing alarm display and power supply.

豫公网安备 41030502000429号

豫公网安备 41030502000429号