TPM equipment management system

TPM equipment management system is a comprehensive set of standardized field operation management software, which is consistent with the concept of TPM. TPM is a theory and a system, and a TPM equipment management system is a tool and a method. The TPM equipment management system can help to realize standard and standardized field operations and standardized event processing procedures under various conditions of all equipment and equipment. The reporting, analysis, log and knowledge base functions of the TPM equipment management system also prompt more personnel to join production and maintenance, creating an environment in which all employees participate.

TPM equipment management system provides a system that allows everyone to work on one platform, and can help all the needs of all personnel in different departments.

The TPM equipment management system ensures the implementation of the "eight elements" in TPM through dedicated research on TPM and a large number of customer surveys with the help of mobile technology, helping enterprises to truly meet the "five six" and "four full" in the practice of TPM system. ”, so that enterprises can establish a more complete and comprehensive production and maintenance system, effectively help TPM solidify and land, and realize the value of TPM.

TPM device management system execution mode:

1. Promote TPM theory to gain the attention of senior leaders and the support of enterprise management systems, and establish a TPM on-site execution system based on the TPM equipment management system.

2. On-site operations are carried out in accordance with standard specifications and procedures, and spot inspections are carried out in accordance with the method of 80% to 100% to realize mobile spot inspection operations.

3. Use the handheld terminal to report 6H, and establish a standard process to eliminate 6H, use the handheld terminal as the medium, establish an electronic visualization system, use the handheld terminal to manage independent maintenance, and reduce the requirements for employee training.

4. Establish a standardized professional maintenance system that conforms to the single-point or combined maintenance strategy, realize the standard active maintenance process, and take 6Z as the goal to create a standard improvement process that serves 6I.

5. Build the TPM equipment management system into an inspection and maintenance work platform that is used by all staff, covering task assignment, operation execution, information exchange, data analysis, operation guidance, problem reporting, experience summary and implementation of maintenance strategies, and becomes the on-site execution of TPM system.

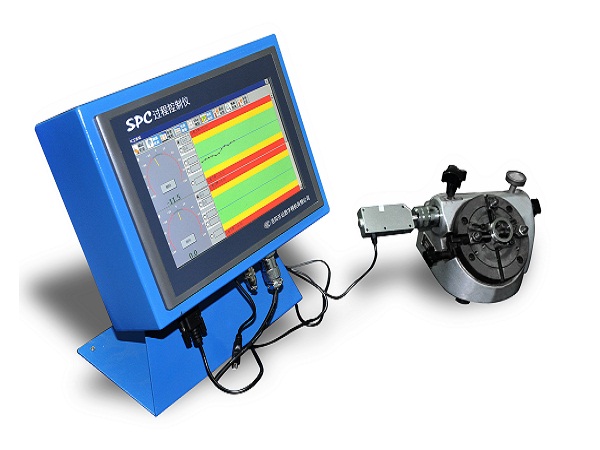

Industrial IoT Device Solutions

1. Production process optimization: The application of Internet of Things technology improves the ability and level of production line process detection, real-time parameter collection, production equipment monitoring, and material consumption monitoring.

2. Product equipment monitoring and management: the integration of various sensing technologies and manufacturing technologies realizes remote monitoring of product equipment operation records and equipment fault diagnosis.

3. Energy management: Realize industrial production and building energy monitoring and management, and truly achieve the goal of energy conservation and emission reduction.

4. Production management: The sensors are embedded and equipped to sense the safety status information of staff, equipment and machines, and the surrounding environment in dangerous environments, so as to realize real-time perception, accurate identification, quick response, and effective control.

TPM设备管理系统应用收益:

通过使用TPM设备管理系统能帮助企业实现以下管理优势:

1、精细化的权限控制

用户根据具体本公司的具体情况,为不同的管理人员分配相应的管理权限(包括总公司查看所有下级单位管理情况,分公司分配自己单位的管理权限)。权限相同的用户,统一建立用户组,权限不同的用户单独设置。维修人员建立工段管理,执行维修时选择派工到工段。

2、循环执行计划

在系统里建立维修、保养计划(或者批量导入excel中的维修保养计划),设置相应的循环周期(天,月,年),系统自动滚动计划,到期提醒用户执行计划,添加相关的执行内容。如果设置的是多次循环计划,本次计划执行完毕后,系统自动滚动到下一次计划中。

3、多级子设备(附属设备)管理

系统支持多级子设备(附属设备)。用户可根据自己管理的设备,为每一个设备增加一个或多个附属设备,子设备还可以添加多个子设备。子设备的管理方式和主设备完全一致,可进行完整的故障报修,维修保养,添加维保计划,循环执行计划。系统支持多级子设备(附属设备)。用户可根据自己管理的设备,为每一个设备增加一个或多个附属设备,子设备还可以添加多个子设备。子设备的管理方式和主设备完全一致,可进行完整的故障报修,维修保养,添加维保计划,循环执行计划。

4、维修、保养日程表管理

维修、保养日常表管理,可以在日常表里一目了然看到本月的计划安排情况,执行情况,未完成情况等不同状态,也可以直接选择具体日期在日程表里添加相应的计划。并能直接查看计划的执行详情情况。导出相应的每一天计划的情况。

5、分析统计和报表

通过分析统计,用户可以自定义分析统计的条件(包括统计的时间,范围),包括进行所在部门设备维修统计(故障率,完好率,停机时间,工作时间),故障报修统计;按年度计划完成情况统计;按维修/保养级别统计;按要出输出各种统计报表,做出正确决策。系统还可以结合生产设备开机运行时间,停机时间,产量,计算设备综合利用率。

TPM管理内容

TPM管理,即“全员生产维修”,70年代起源于日本,是一种全员参与的生产维修方式,其主要点就在“生产维修”及“全员参与”上。通过建立一个全系统员工参与的生产维修活动,使设备性能达到。TPM管理包括以下几种类别:

1、事后维修----BM(Breakdown Maintenance) 这是早期的维修方式,即出了故障再修,不坏不修。

2、预防维护--PM(Preventive Maintenance) 这是以检查为基础的维修,利用状态监测和故障诊断技术对设备进行预测,有针对性地对故障隐患加以排除,从而避免和减少停机损失,分定期维修和预知维修两种方式。

3、改善维护--CM(Corrective Maintenance) 改善维修是不断地利用的工艺方法和技术,改正设备的某些缺陷和先天不足,提高设备的性、可靠性及维修性,提高设备的利用率。

4、维护预防--MP(Maintenance Prevention) 维修预防实际就是可维修性设计,提倡在设计阶段就认真考虑设备的可靠性和维修性问题。

从设计、生产上提高设备品质,从根本上防止故障和事故的发生,减少和避免维修。

5、生产维护--PM(Productive Maintenance) 是一种以生产为中心,为生产服务的一种维修体制。它包含了以上四种维修方式的具体内容。对不重要的设备仍然实行事后维修,对重要设备则实行预防维修,同时在修理中对设备进行改善维修,设备选型或自行开发设备时则注重设备的维修性(维修预防)。

豫公网安备 41030502000429号

豫公网安备 41030502000429号