|

Product Usage

|

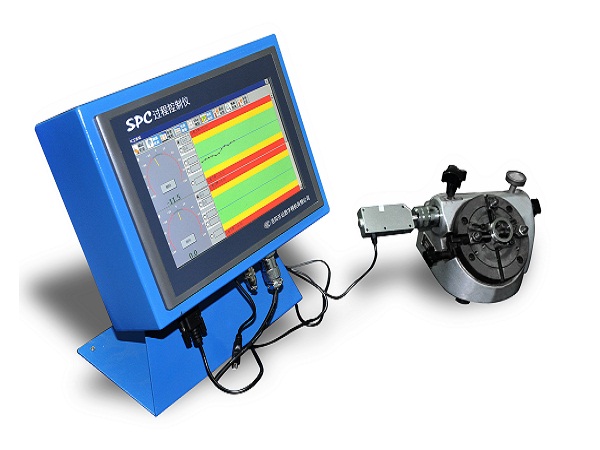

It is applied to the bearing SPC process control in the manual sampling mode, especially suitable for pairing with the machine tool and used by the machine tool operator.

|

As the upper computer monitoring device, it performs data collection, analysis and feedback functions for the lower computer (SPC process controller).

|

For enterprises to build SPC network architecture

|

Management tentacles reaching out to the workshop

|

The C-MES system is a production information management system oriented to the executive layer of the workshop of manufacturing enterprises.

|

|

Performance overview

|

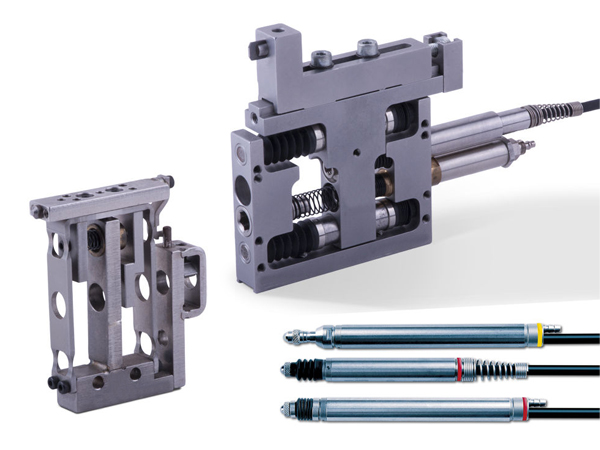

The operator's existing working mode, that is, the special bearing detection measuring tool, remains unchanged, and the original mechanical watch is replaced with an SPC unit composed of an industrial human-machine interface embedded in software and several displacement sensors, so as to realize digital measurement and analysis. The industrial human-machine interface embedded in the SPC process control software is used as the data processing center, and the high-precision displacement sensor and the SPC data acquisition and conversion hardware are used as the sampling module to realize the digital measurement, data acquisition and analysis and remote data communication of the parts on the product manufacturing site. Provide various control charts including Xbar-R and process control parameters such as Cp, Cpk, Pp, Ppk, Cmk.

|

The SPC data query station is composed of a large-screen touch color screen, an industrial computer (including keyboard, mouse and other accessories) and a cabinet; it is installed with an embedded SPC system server analysis software, which can be installed at the production line-end, through RS485 wired or wireless industrial network and multiple A SPC process control instrument is connected, and the real-time measurement data of the underlying instrument is obtained through real-time communication for summary, analysis, display and feedback; at the same time, data sharing is realized through the factory LAN and each terminal computer installed with the SPC system client analysis software。

|

For large-scale bearing enterprises to build SPC network architecture, they need to do:

●In each workshop or production line, a first-level SPC network is composed of several SPC process controllers and SPC data query stations, and the network data communication is mainly in the industrial RS485 mode;

●SPC data query station as a server (customers can also configure a server) and each user computer (client) in the factory to form a secondary SPC network, the network data communication is the factory local area network;

●SPC server software can be installed in the server computer to perform upload and download tasks;

●SPC client software can be installed in the client computer (unlimited number) to support factory managers to query front-line production data in real time

|

Tracking function

Supervision function

control function

management function

Information query function

|

C-MES can provide enterprises with manufacturing data management, planning scheduling management, production scheduling management, inventory management, quality management, human resource management, work center/equipment management, tooling management, procurement management, cost management, project Kanban management , production process control, bottom-level data integration analysis, upper-level data integration and decomposition and other management modules to create a solid, reliable, comprehensive and feasible manufacturing collaborative management platform for enterprises. (Provide customized software service)

|

豫公网安备 41030502000429号

豫公网安备 41030502000429号