Product Usage

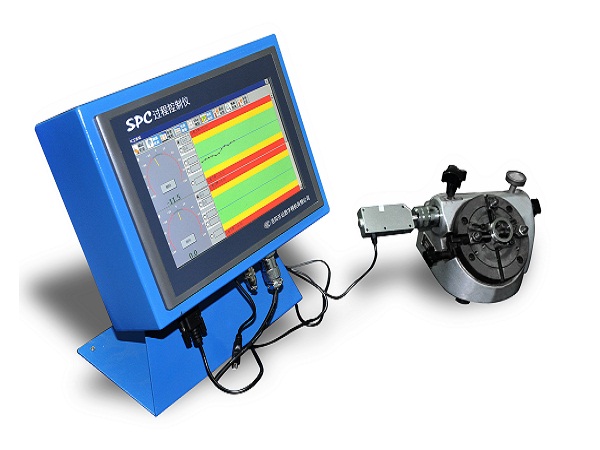

It is applied to the bearing SPC process control in the manual sampling mode, especially suitable for one-to-one pairing with the machine tool and used by the machine tool operator.

Performance overview

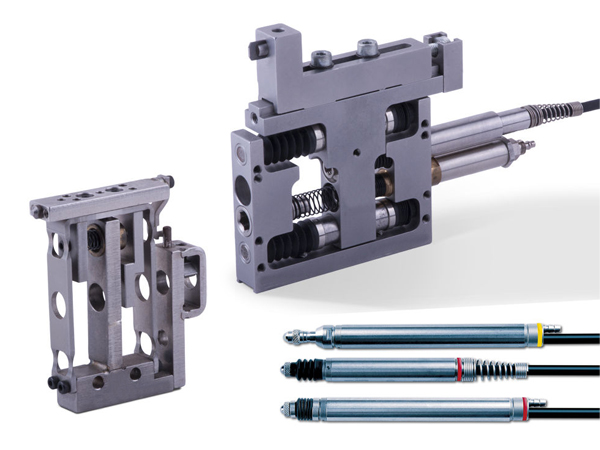

Continue the existing working mode of the operator, that is, the special bearing detection measuring tool, and replace the original mechanical watch with an SPC unit composed of an industrial human-machine interface embedded in software and several displacement sensors, so as to realize digital measurement and analysis.

Taking the industrial man-machine interface embedded in the SPC process control software as the data processing center, and using the high-precision displacement sensor and the SPC data acquisition and conversion hardware as the sampling module, the digital measurement, data acquisition and analysis and remote data communication of the parts on the product manufacturing site are realized. Provide various control charts including Xbar-R and process control parameters such as Cp, Cpk, Pp, Ppk, Cmk.

豫公网安备 41030502000429号

豫公网安备 41030502000429号