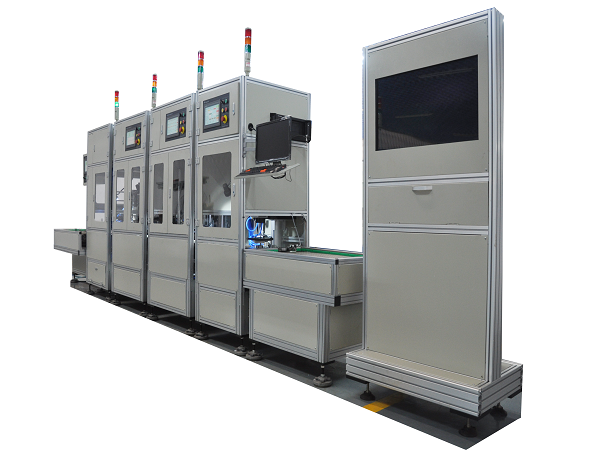

Automatic tensioner assembly line

The tensioning pulley is a belt-driven tensioning device. Its function is to change the wrap angle of the pulley or control the tensioning force of the belt and press the follower pulley on the belt. Its main structure includes a friction unit, a torsion spring, a bearing, a pulley and some widgets. The automatic tensioner assembly line is to standardize these components to make them meet the needs of the tensioner, and automate the assembly of the tensioner.

The automatic tensioner assembly line is suitable for the automatic on-line assembly of the tensioner, which can replace manual labor and realize the automatic detection, automatic assembly, automatic marking and full-line data statistics and analysis of the automobile tensioner assembly process. The automatic tensioner assembly line is a production line with 4 machines and requires 3 operators. It can realize the functions of bearing assembly, assembly assembly, torque and damping detection, tightening height measurement, automatic press-fitting and other functions.

Advantages and characteristics of automatic tensioner assembly line

1. Fully automatic assembly, high cost performance, one equipment is equivalent to four equipment functions

2. Save labor cost, can save 3-5 people, one person is responsible for double-station production

豫公网安备 41030502000429号

豫公网安备 41030502000429号