Introduction to Tensioner/Idler Assembly Line

Work object: Auto tensioner, manual adjustment of tensioner

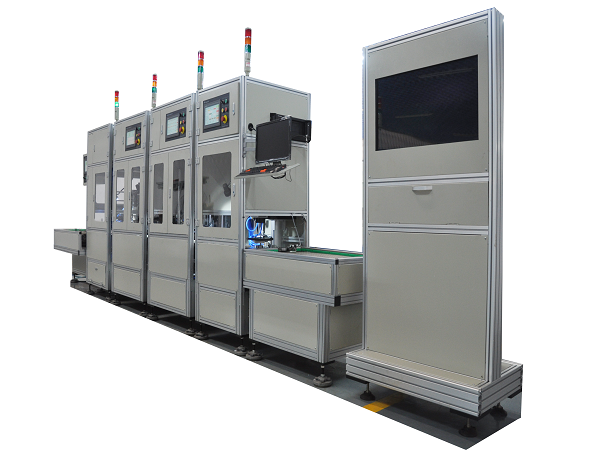

Equipment Style: Automobile Automatic Tensioner Assembly Line Auto Automatic Tensioner Robot Assembly Inspection Production Line

Equipment name: Automobile automatic tensioner assembly line Automobile automatic tensioner robot assembly and testing production line

Equipment model: HD-00 RZJL-00-R

Scope of work: Automatic tensioner products

Equipment use: Replace manual labor, realize automatic detection, automatic assembly, automatic marking, and full-line data statistics and analysis during the assembly process of automobile tensioner

Technical indicators

●HD01 feeding machine visual inspection device - automatic feeding and visual inspection before assembly

●HD02 Inner and Outer Diameter Separator and Fitting Machine One by One Automatically measure and assemble the inner and outer parts of the tensioner bearing

The HD03 intelligent press-fit and pull-out force testing machine press-fits the parts assembled in the previous process and detects the pull-out force

●HD04 metal dust cover automatic press-fitting machine press-fit metal dust cover one by one

●HD05 Radial Clearance Automatic Testing Machine - Automatically detect the radial clearance of finished bearings

●HD06 pin automatic pressing machine one by one automatic pressing pin

●HD07 automatic vibration measuring machine - automatic detection of tension wheel vibration (noise)

●HD08 laser marking machine automatically prints product logos one by one

●HD09 automatic material sorting machine finished material sorting

●HD10 whole line assembly information query station collects the data of the whole line equipment operation, testing and MES system

①Automatic tensioner press ft machine;

②Automatic tensioner assembly and inspection machine;

③Automatic tensioner screw tightening machine;

④Laser marking machine;

⑤Truss robot;

⑥Joint robot;

⑦Data query station;

⑧Assembly and inspection components.

Technical Features Fully automatic assembly, high cost performance Labor saving: 3 to 5 people can be effectively saved

豫公网安备 41030502000429号

豫公网安备 41030502000429号