Bearing intelligent maintenance software and hardware system

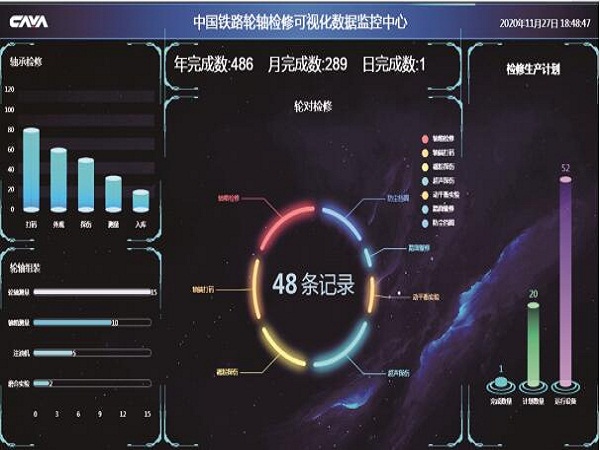

a) It has the function of CCD intelligent recognition of characters, forms a two-dimensional code, and engraves a two-dimensional code that is consistent with the inherent information requirements of the bearing for each set of bearings. The detection process is scanned by a code scanner, and the bearing detection information is automatically transmitted to the server;

b) Through the QR code scanning technology, the old mode of "manual observation, manual recording" was changed and upgraded to a digital acquisition mode of "manual observation, QR code reading, touch-screen confirmation" when overhauling bearing magnetic particle inspection;

c) It not only improves the measurement accuracy, but also avoids manual input errors, and realizes the automatic input of bearing inspection data and automatic bearing selection;

After the clearance detection equipment is modified, the database is read, and the data is automatically uploaded to the server;

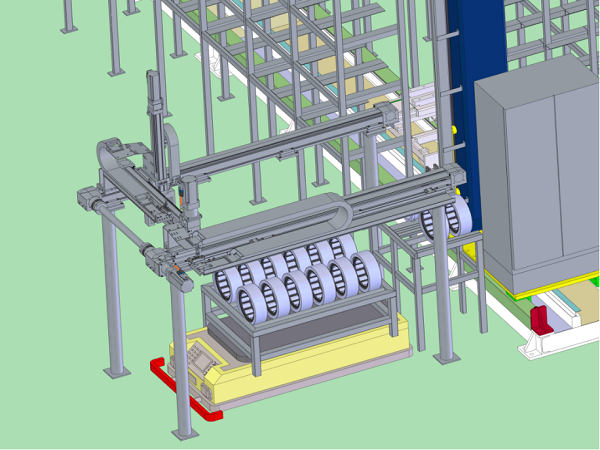

d) The automatic detection machine for the inner and outer rings of the bearing scans the code through the QR code, so that the monitoring letter is automatically uploaded for data aggregation, and the 6-degree-of-freedom robot is used for loading and unloading, which realizes the automation of the operation process;

● Application of quality traceability technology with CCD character intelligent recognition and two-dimensional code as characteristic code;

● Replace traditional mechanical measurement with high-precision digital measurement;

● The realization of automatic detection function of automatic detection and robot loading and unloading;

● Whole line data statistics, analysis, intelligent alarm;

● Establishment of digital warehouse and intelligent matching group assembly;

● Process enforcement, paperless operation, and minimize human interference.

豫公网安备 41030502000429号

豫公网安备 41030502000429号