Brief Introduction of Brake Valve Intelligent Maintenance Software and Hardware System

●Brake valve intelligent maintenance software and hardware system In the maintenance process management system, it can improve the work efficiency of valve maintenance, comprehensive management of maintenance data, stored data query and table printing at any time, and the entire maintenance process is connected with the system in the unit. Realize remote data query;

●With RFID reading as a breakthrough, it realizes the intelligent management of all maintenance data, and implements electronic ledger, inquiry and printing forms;

●Improve maintenance quality and strictly manage;

●The combination of database association and Internet technology enables all maintenance data to be automatically backed up, providing a strong security guarantee for the use of hardware and software for remote query of maintenance results in the future.

The status quo of traditional valve maintenance

1. Inter-process operations, manual transcription, manual data input;

2. There will be errors and omissions in the operation process, and the maintenance process data cannot be summarized, real-time query, and process monitoring;

3. The control valve and three-valve maintenance process does not realize data sharing and intelligent management of the entire maintenance process;

4. Manual trolleys transfer materials between processes, which is labor-intensive and low-efficiency.

specific plan

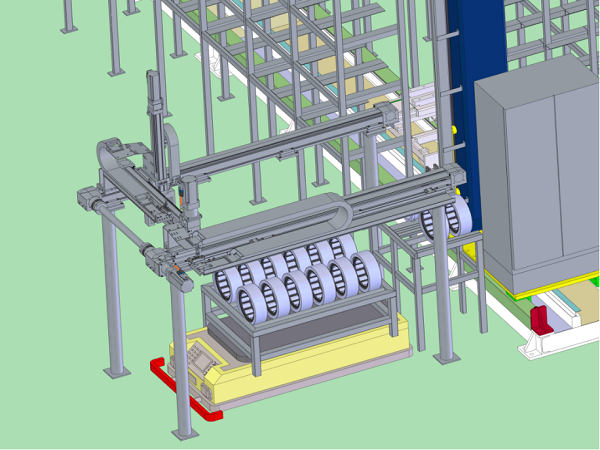

RFID tags are installed on material trays, and RFID code readers are installed in each maintenance process to automatically read material numbers and realize material traceability;

●Each station is equipped with station machine, maintenance data computer input, wireless upload server;

The experimental data is automatically collected from the testing machine, automatically uploaded to the server, information is summarized, and information is shared for quality monitoring;

AGV trolley intelligently transfers materials between processes;

After the overhaul, use the digital torque wrench to accurately tighten and collect torque information during assembly, and automatically upload it to the server;

●Establish a comprehensive data query station for query and statistical analysis of maintenance data.

The overall goal of the program is achieved

goal achievement

●With RFID tags and RFID code reading as technical features;

Play the role of quality supervision and smart card control between processes;

●Accurately record the process maintenance data and automatically upload it to the server;

Real-time collection of valve experimental data and upload to the server;

●The whole maintenance process realizes intelligent management and data sharing through local area network.

Intelligent management

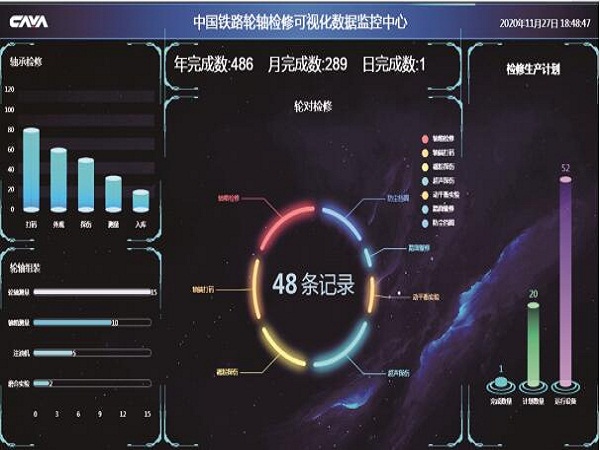

● The whole line data statistics, analysis, intelligent alarm, establish electronic ledger;

● Establishment and intelligent management of digital warehouse;

● Process mandatory, paperless operation, minimize human interference as much as possible.

Features

1. Realize the intelligent management of the whole valve maintenance process;

2. Improve the quality of maintenance;

3. Smooth operation;

4. Safe and reliable.

豫公网安备 41030502000429号

豫公网安备 41030502000429号