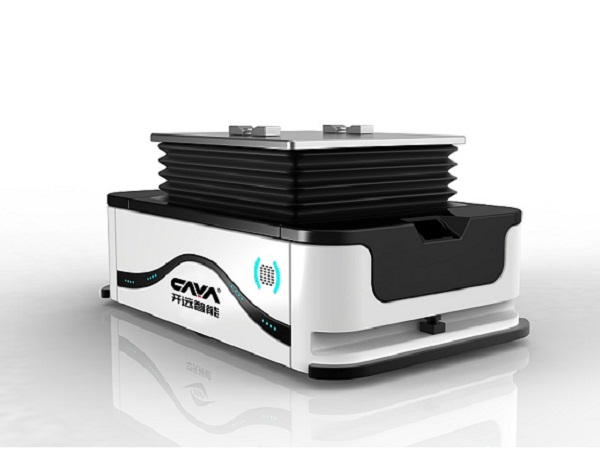

AGV (Automated Guided Vehicles) trolley

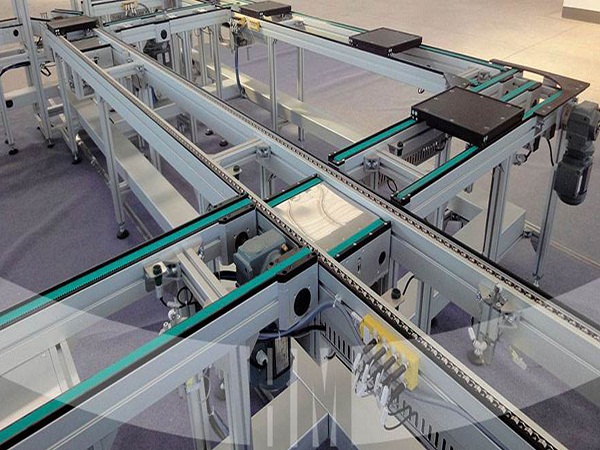

AGV (Automated Guided Vehicles) is also known as unmanned guided vehicle, automatic guided vehicle, and laser guided vehicle. Its distinctive feature is unmanned driving. The AGV is equipped with an automatic guidance system, which can ensure that the system can automatically travel along a predetermined route without manual piloting, and automatically transport goods or materials from the starting point to the destination. Another feature of AGV is good flexibility, high degree of automation and high level of intelligence. The travel path of AGV can be flexibly changed according to changes in storage space requirements, production process flow, etc., and the cost of changing the travel path is the same as that of traditional conveyor belts. Very inexpensive compared to rigid transmission lines. AGVs are generally equipped with a loading and unloading mechanism, which can automatically interface with other logistics equipment to automate the entire process of loading, unloading and handling of goods and materials. In addition, AGV also has the characteristics of clean production. AGV relies on its own battery to provide power. There is no noise and pollution during operation. It can be used in many places that require a clean working environment.

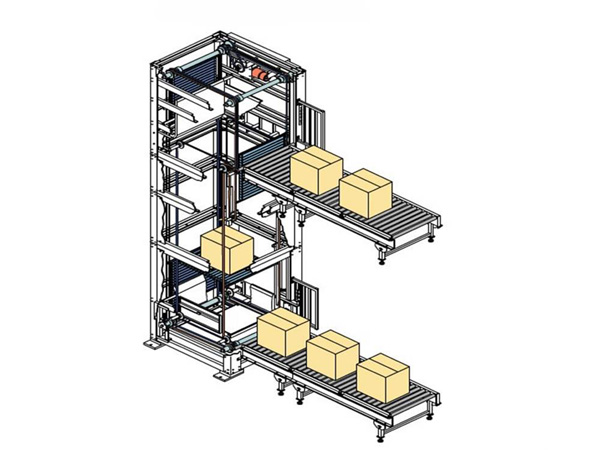

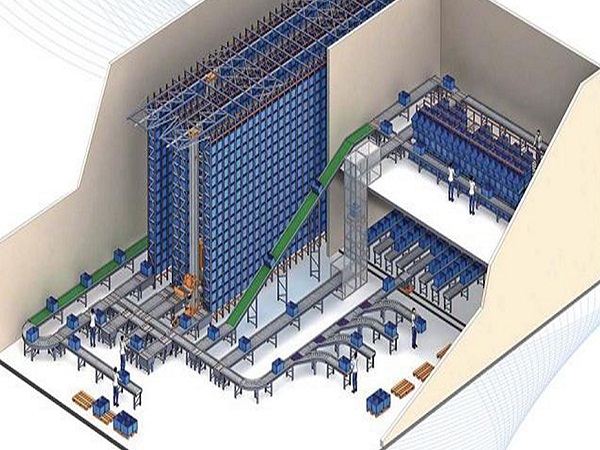

AGV plays a big role in the production line of the manufacturing industry, and completes the material handling tasks efficiently, accurately and flexibly. And a flexible logistics handling system can be formed by multiple AGVs. The handling route can be adjusted in time with the adjustment of the production process, so that a production line can produce more than a dozen products, which greatly improves the flexibility of production and the competitiveness of enterprises. In 1974, in order to improve the flexibility of the transportation system, the Volvo Kalmar car assembly plant in Sweden adopted an automatic car assembly line based on AGVS as a carrier. 20% reduction in assembly failures, a 39% reduction in assembly failures, a 57% reduction in payback time, and a 5% reduction in labor. AGVs have been widely used in the manufacturing and assembly lines of major automobile factories in the world, such as General Motors, Toyota, Chrysler, Volkswagen, etc.

In recent years, as the basic handling tool of CIMS, the application of AGV has penetrated into many industries such as mechanical processing, home appliance production, microelectronics manufacturing, cigarettes, etc. The production and processing field has become a field where AGV is widely used.

豫公网安备 41030502000429号

豫公网安备 41030502000429号