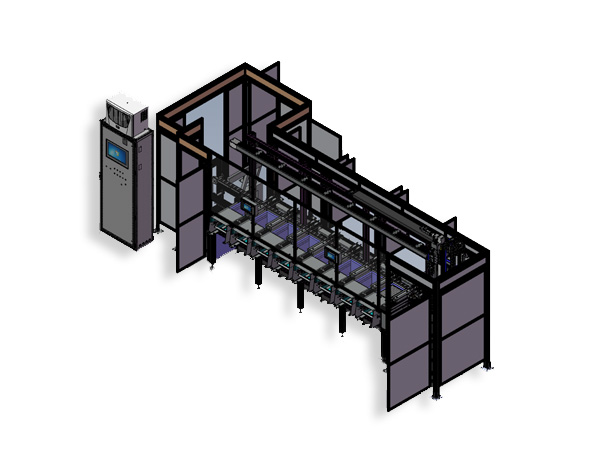

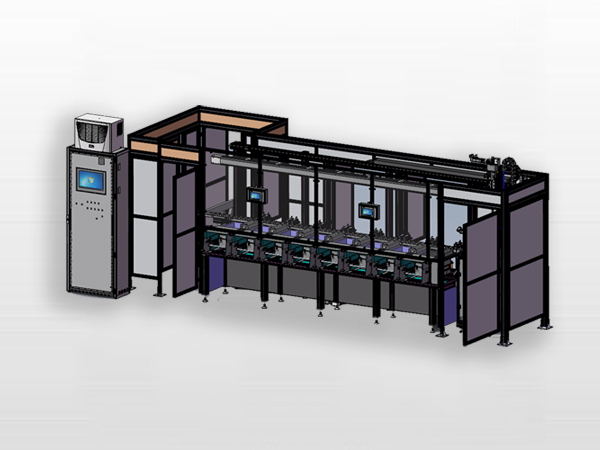

Large size bearing rolling element sub-assembly box machine

Bearing is an important structural part to ensure the rotation accuracy of the machine. It consists of four parts: outer ring, inner ring, rolling body and cage. From raw materials to finished products, the bearing must go through rough forging, rough machining, finishing, and assembly of each component. Cleaned, capped, oiled, and then packed in boxes to leave the factory.

The large-size bearing rolling element sub-assembly box machine replaces the manual method with machinery, and the automatic sub-assembly box machine replaces the previous bearing processing. After the bearing has been oiled, workers are required to hold the box and box cover in their hands. Manual boxing process and use the equipment to automatically set the workflow to complete the overall cartoning work.

Advantages of large-size bearing rolling element sub-assembly box machine

On the one hand, the efficiency of cartoning is low, which affects the speed of cartoning and packaging of bearings. On the other hand, it increases the labor intensity of workers and the input of labor remuneration for workers, thereby reducing the overall production efficiency and cost.

豫公网安备 41030502000429号

豫公网安备 41030502000429号